Our world today produces a lot of waste that needs to be handled right. Turning old items into new resources is key to our environmental duty.

This metal recycling guide takes you through the whole process, from picking up to reusing. We’ll see how recycling helps businesses and communities a lot.

Learning about these steps helps everyone, from companies to homes, to manage metals better. It saves our planet’s resources, cuts down on landfill waste, and uses less energy.

Let’s dive into the good it does for our planet and the money it saves. Our guide will help you make smart choices about what to throw away and what to keep.

Understanding Metal Recycling and Its Global Significance

Metal recycling is more than just reducing waste. It’s key to managing resources sustainably, protecting the environment, and boosting economies and societies worldwide.

Defining Metal Recycling in the Circular Economy

Metal recycling is a core part of the circular economy. It’s different from old ways of making and using things. The circular economy keeps materials going round and round, not just used once and then thrown away.

This way, what would be waste becomes something valuable again. It helps create systems that are better for the planet. It’s a big change from our old “take-make-dispose” way of doing things.

- Extended material lifespan through repeated recovery and reprocessing

- Reduced reliance on virgin raw material extraction

- Energy conservation through efficient processing methods

- Minimised environmental degradation associated with mining operations

This method keeps metals useful for longer. It helps the economy and protects the environment at the same time.

The Role of Metal Recycling in Sustainable Development

Metal recycling helps meet many United Nations Sustainable Development Goals. It’s good for the planet and can make businesses more successful.

Recycling saves a lot of energy. For example, recycling aluminium uses 95% less energy than making it from scratch. This means less pollution and a smaller carbon footprint for factories.

Companies see recycling as part of being responsible. They include recycling goals in their reports. This shows they care about the planet and their profits.

“Sustainable metal management represents one of the most effective strategies for reducing industrial environmental impact while maintaining economic growth.”

Recycling can also make money. People and businesses can earn from recycling aluminium cans and other metals. This makes sustainable practices more appealing and helps more people join in.

Recycling efforts are growing worldwide. Countries are linking saving resources, growing economies, and protecting the environment. The growth of recycling facilities shows a strong commitment to sustainable development.

Categories of Recyclable Metals: Ferrous and Non-Ferrous

Knowing the main types of metals is key to recycling well. The recycling world splits metals into two main groups. These groups are based on how much iron they have and if they are magnetic. Each group has its own recycling ways and values.

Ferrous Metals: Iron, Steel, and Their Alloys

Ferrous metals are very important in recycling. They are used a lot and are magnetic, making them easy to sort. This group includes steel, cast iron, and wrought iron. Together, they make up the biggest part of recycled metals worldwide.

Common Sources and Recycling Rates

Ferrous metals are in many things we use every day. They are in building beams, car parts, and even home appliances. Cars, for example, have about 65% steel and iron by weight.

Recycling rates for ferrous metals are very high. Steel recycling rates are almost 90% in many countries. This is because they are magnetic and easy to sort.

Non-Ferrous Metals: Aluminium, Copper, and Precious Metals

Non-ferrous metals don’t have iron, so they’re not magnetic and don’t rust easily. This group includes aluminium, copper, brass, lead, zinc, and precious metals like gold and silver.

To learn more about these metals, check out this guide on non-ferrous versus ferrous metals.

Unique Properties and Recycling Challenges

Non-ferrous metals have special qualities that make them great for recycling. Aluminium is light and doesn’t rust, making it good for packaging and planes. Copper is great for wiring and electronics because it conducts electricity well.

Aluminium recycling saves a lot of energy, up to 95%. But, it’s hard to keep it clean from other materials. Copper recycling keeps the metal’s properties the same, but it’s tricky to separate it from other materials.

Precious metals are also tricky to recycle. They’re found in small amounts in electronics, needing special ways to get them out. The methods for recycling these metals are getting better as technology improves.

Even with the challenges, recycling non-ferrous metals is worth it. It saves money and helps the environment. New ways to separate and process these metals are being developed all the time.

The Complete Metal Recycling Process

Turning old metal into new materials is a complex journey. It mixes mechanical steps with high-temperature changes. This method helps get the most value from materials and keeps the environment clean.

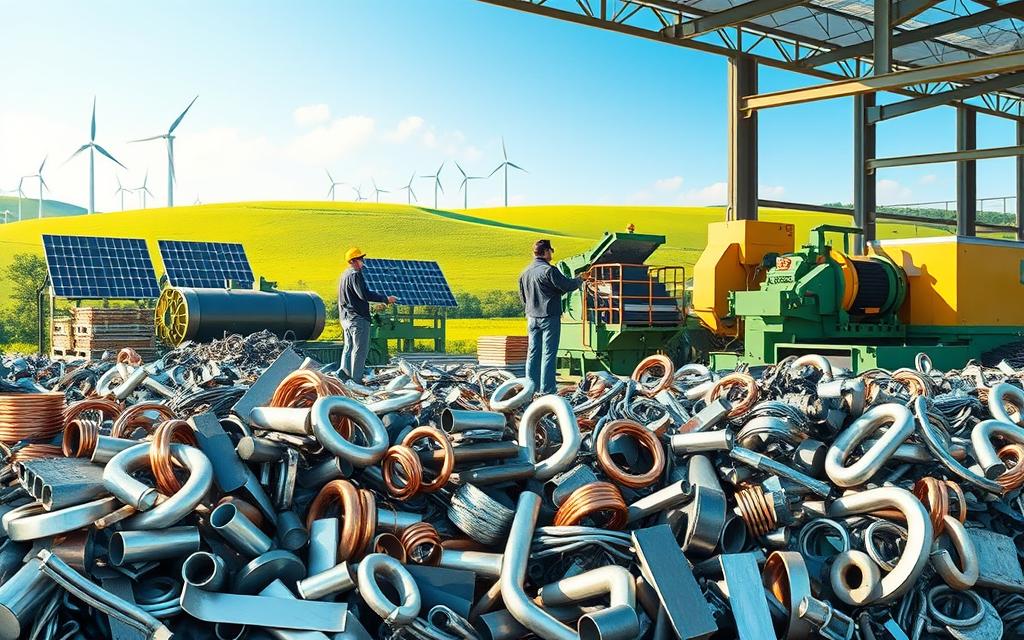

Initial Collection and Transportation of Scrap Metal

The first step is scrap metal collection. Systems gather materials from many places. This is the key start of recycling.

Methods: Curbside, Drop-Off, and Commercial Collection

People put metal in bins for curbside collection. There are also drop-off centres for big items. Commercial services pick up from work sites.

Special trucks carry metals to recycling places. These trucks have magnets and presses to save space.

Sorting and Separation Techniques

Metal sorting uses advanced tech to sort metals. This step affects the quality and value of recycled materials.

Manual and Automated Sorting Technologies

First, people remove big contaminants and sort metals. Then, machines take over. They use:

- Magnetic separators for iron

- Eddy current separators for non-iron metals

- Infrared scanners for metal types

- Air classification systems for light materials

Processing: Shredding, Shearing, and Baling

Size reduction makes metals ready for melting. It increases surface area and removes dirt.

Equipment Used and Efficiency Considerations

Shredders break down big items with hammers. Shears cut metal with hydraulic force. Balers make metals into blocks for melting.

| Processing Method | Equipment Type | Typical Capacity | Energy Efficiency |

|---|---|---|---|

| Shredding | Hammer Mill | 10-100 tonnes/hour | High |

| Shearing | Hydraulic Shear | 5-50 tonnes/hour | Medium |

| Baling | Vertical Baler | 2-20 tonnes/hour | Very High |

Melting and Purification in Furnaces

The melting process turns scrap into molten metal. This stage needs careful temperature control.

Types of Furnaces and Temperature Controls

There are different furnaces for various metals. Electric arc furnaces are good for steel. Aluminium and copper use reverberatory furnaces. Induction furnaces are for special alloys.

Modern furnaces have computer controls. These keep the melting process efficient and save energy.

Solidification and Fabrication into New Products

Molten metals are cooled and shaped into new products. This is the recycling cycle’s end.

Casting, Rolling, and Final Product Manufacturing

Casting pours metal into moulds for basic shapes. Rolling mills make metal thinner. Extrusion creates long profiles for building and making.

After, the metal is tested for quality. Recycled metals often match or beat new metal standards.

Environmental Benefits of Metal Recycling

Metal recycling has big environmental wins. It saves energy and protects our planet. Recycling is key to making industries more sustainable.

Energy Conservation and Reduction in Consumption

Recycling metals uses much less energy than making them from scratch. This saves fossil fuels and cuts down on carbon emissions.

Recycling skips the energy-hungry mining and processing steps. This makes recycling very efficient for many metals.

Comparative Data: Recycled vs. Virgin Metal Production

Recycling metals is a big win for energy savings. Here are some impressive numbers:

| Metal Type | Virgin Production Energy | Recycled Production Energy | Energy Savings |

|---|---|---|---|

| Aluminium | 170 MJ/kg | 8.5 MJ/kg | 95% |

| Steel | 32 MJ/kg | 8 MJ/kg | 75% |

| Copper | 100 MJ/kg | 35 MJ/kg | 65% |

These big energy cuts show why recycling metals is a top energy conservation move for industries.

Preservation of Natural Resources and Ecosystems

Recycling metals cuts down on mining harm. It means less land damage, water use, and habitat loss.

Choosing recycling over mining keeps natural resources safe. It helps keep biodiversity and protects ecosystems from harm.

Impact on Mining Activities and Habitat Protection

Mining harms wildlife and natural habitats. Recycling lowers the need for new mining, helping protect these areas.

Recycling a tonne of steel saves a lot of resources. It saves iron ore, coal, and limestone, and also water and land.

Minimisation of Landfill Waste and Pollution

Recycling metals keeps them out of landfills. This stops harmful substances from getting into soil and water.

Recycling also saves space for waste. This is important as landfills run out of room worldwide.

Reduction in Air and Water Contaminants

Recycling metals makes less pollution than making them from scratch. This improves air and water quality.

Recycling aluminium cuts air pollution by 95% and water pollution by 97%. Similar benefits apply to other metals, making recycling a green choice.

Recycling also cuts greenhouse gas emissions. The aluminium industry could lower global emissions by 2% if recycling rates were higher.

Economic Advantages and Cost Savings

Metal recycling brings big wins for businesses, consumers, and communities. It turns waste into valuable resources, creating a cycle of profit. This is good for everyone involved.

Financial Benefits for Manufacturers and Consumers

Using recycled metals saves manufacturers a lot of money. For example, making aluminium from recycled materials uses 95% less energy. This means big savings for them.

These savings often mean cheaper products for us. The car industry is a great example. Cars made with recycled steel and aluminium stay affordable, even when raw material prices go up.

Companies that recycle find new ways to make money. What used to be waste now brings in cash. This change makes recycling a profitable venture.

Market Trends and Price Volatility in Recycled Metals

Recycled metals are global commodities, influenced by supply and demand. Today, more manufacturers want sustainable and affordable materials. This is good for the market.

Prices can change, but the trend is towards recycled materials. Growing industries and green projects keep demand high.

| Metal Type | Price Stability | Demand Growth (2020-2023) | Primary End Users |

|---|---|---|---|

| Recycled Aluminium | Moderate | 18% | Automotive, Packaging |

| Recycled Copper | High Volatility | 22% | Electronics, Construction |

| Recycled Steel | Stable | 15% | Construction, Manufacturing |

| Recycled Precious Metals | Extreme Volatility | 25% | Electronics, Jewelry |

Job Creation and Economic Growth in the Recycling Sector

The recycling industry creates lots of jobs. It offers work for people with different skills. This helps the economy grow.

Local areas get jobs in recycling plants and services. These jobs pay well and are stable. They help communities all over.

“Metal recycling is a strong growth area for jobs in America. It offers good wages without needing a degree.”

Recycling also helps other industries grow. Companies that make equipment, handle logistics, and do engineering get more work. This is because recycling needs their help.

Employment Statistics and Industry Expansion

Recycling jobs are growing fast. Over 500,000 people work in recycling directly. Many more work in related fields.

Experts say recycling jobs will keep growing. The Bureau of Labor Statistics predicts an 8% increase in recycling jobs over the next ten years. This is faster than many other industries.

There are many types of jobs in recycling:

- Collection and sorting specialists

- Processing equipment operators

- Quality control technicians

- Logistics and transportation coordinators

- Sales and market analysts for recycled materials

The benefits of recycling are clear. It saves money for manufacturers and creates lots of jobs. This makes recycling a key part of our economy.

Technological Advancements in Metal Recycling

The metal recycling industry is changing fast thanks to new technologies. These innovations make recycling more efficient and better for the environment. They help sort metals better and use less energy.

Innovations in Sorting and Processing Equipment

Recycling places now use advanced equipment. This equipment sorts metals quickly and accurately. It uses sensors and scanners to check what each piece is.

Automated systems with weighing and ID features are common. They work all the time without getting tired. This means the metals are purer and cleaner.

AI and Robotics in Metal Separation

Artificial intelligence is changing how we sort metals. AI systems learn to spot different metals and contaminants. They make decisions based on what they see and what the materials are like.

Robots with special grippers sort metals with precision. They work with people, doing tasks that are dangerous or boring. AI and robots together make recycling safer and more consistent.

Advances in Melting and Purification Technologies

New melting technologies use less energy and make better metal. Modern furnaces have smart controls that adjust temperature and melting time. They change settings based on the scrap material.

Purification methods have also improved. New filters and treatments remove impurities better. This means the recycled metal is of higher quality.

Energy-Efficient Furnaces and Emission Controls

Today’s furnaces save energy and protect the environment. They use regenerative burners that reuse waste heat. This cuts fuel use by up to 30%.

Modern recycling plants also have better emission controls. These systems filter out harmful gases and particles. They check emissions all the time to meet environmental rules.

| Technology Type | Key Features | Benefits | Implementation Level |

|---|---|---|---|

| AI Sorting Systems | Machine learning algorithms, visual recognition | 95% accuracy, reduced labour costs | Growing adoption in large facilities |

| Robotic Separation | Precision grippers, 24/7 operation | Consistent quality, improved safety | Moderate adoption in advanced plants |

| Energy-Efficient Furnaces | Heat recovery systems, smart controls | 30% energy savings, lower emissions | Widely implemented in new facilities |

| Advanced Emission Controls | Multi-stage filtration, real-time monitoring | 95% pollutant capture, regulatory compliance | Standard in modern recycling plants |

The future of metal recycling looks bright. New trends include sorting systems for electronic waste and furnaces that emit almost nothing. These advancements will make recycling even better.

Experts think the recycling industry will use more IoT devices soon. These devices will help make recycling more efficient and sustainable. Technology keeps improving, making recycling better for our planet.

Challenges Facing the Metal Recycling Industry

Despite its many benefits, the metal recycling industry faces big challenges. These issues affect how well it works and its impact on the environment. The industry needs to keep finding new ways to stay effective and sustainable.

Contamination and Quality Assurance Issues

One big problem in metal recycling is contamination. Non-metal materials often get mixed in with scrap metal. This can make the recycled materials less valuable and less useful.

Common Contaminants and Their Impact on Recycling

Many substances cause problems in recycling. Paint, oil, and dirt are common contaminants. They can make it harder to melt the metal and affect its quality.

Plastic, rubber, and chemicals also cause issues. Even a little bit of these can make a whole batch unusable for high-quality uses.

The table below shows common contaminants and how they affect recycling:

| Contaminant Type | Common Sources | Impact on Recycling Process | Quality Implications |

|---|---|---|---|

| Paint and Coatings | Automotive parts, household items | Increased furnace emissions, slag formation | Reduced metal purity, surface defects |

| Oil and Grease | Machinery components, automotive scrap | Combustion risks, air pollution | Porosity in final products |

| Plastic Attachments | Electronic waste, packaging materials | Clogging equipment, chemical contamination | Inconsistent alloy composition |

| Dirt and Soil | Construction scrap, outdoor equipment | Abrasion damage to machinery | Inclusion defects in cast products |

Regulatory and Infrastructural Barriers

The metal recycling industry faces many challenges. These include environmental rules and physical limits. These issues add to the technical problems.

Compliance with Environmental Laws and Logistics

Regulatory compliance is a big deal. Recycling places must follow changing environmental laws. This includes rules on emissions, waste, and worker safety.

Getting permits can take a long time. Facilities need to show they meet air quality and waste management standards. They must use detailed monitoring systems.

Logistical infrastructural barriers are also a problem. It’s hard to collect scrap metal efficiently. Many places lack recycling facilities, making transport expensive and bad for the environment.

Getting new sorting technology is hard. It costs a lot of money. Many recycling places struggle to afford the latest equipment.

How to Participate in Metal Recycling: Practical Tips

Recycling metals is easy and doesn’t need special skills or tools. Both people and businesses can help a lot by following simple steps. This guide will show you how to get involved at any level.

For Households: Effective Sorting and Disposal Methods

Recycling starts at home with sorting and preparing metals. Many household items, like cans and foil, are recyclable but often get thrown away.

Guidelines for Identifying and Preparing Recyclable Metals

First, check what your local recycling centre accepts. They usually take aluminium cans, tin, and clean foil. They might also accept small appliances and kitchenware.

Here’s how to prepare items for recycling:

- Rinse containers to remove food residue

- Remove non-metal parts when you can

- Keep different metals apart if needed

- Flatten aluminium cans to save space

- Look for local recycling points or curbside services

If you want to do more, there are many online resources for advanced recycling projects. Always be careful when handling sharp metal.

For Businesses: Implementing Recycling Programmes

Businesses produce a lot of metal waste, like packaging and equipment parts. Starting recycling programmes shows you care about the environment and can save money too.

Strategies for Waste Reduction and Corporate Responsibility

Good recycling starts with knowing where your waste comes from. Then, set up a system to collect it. Here are some tips:

- Put recycling bins in key places

- Train staff on how to sort

- Work with certified recyclers

- Keep track of how well you’re doing

- Tell others about your green efforts

Going beyond just collecting, look at ways to use less metal. Use lighter packaging, choose materials wisely, and improve your processes. This all helps the planet.

Companies find that good recycling not only helps the environment but also gets them praised by the community. It can even lead to tax benefits. Starting with the right bins and training staff is a smart investment that saves money in the long run.

Global Trends and the Future of Metal Recycling

The metal recycling industry is at a turning point, with global trends pointing towards a greener future. We see big differences in how recycling works around the world. New technologies are set to change how we get and use valuable materials.

Current Recycling Rates and Regional Differences

Recycling rates for metals vary a lot from place to place. Some countries have set up good recycling systems, while others are just starting out.

Progress in the United States and Worldwide

In the United States, recycling of metals like aluminium and steel has improved a lot. About 50-60% of aluminium cans are recycled, but this can change a lot depending on where you are.

In Europe, countries like Germany and Austria lead in recycling. They have high recovery rates thanks to strong recycling policies and public support.

Developing countries face big challenges, like informal recycling and limited facilities. But, they are working hard to improve recycling and create jobs.

Future Outlook: Innovations and Policy Developments

The future of metal recycling looks bright, thanks to new tech and changes in laws. More people and governments see the value in recycling for both the planet and the economy.

Predictions for Technology and Sustainability Goals

Here are some big changes expected in metal recycling soon:

- Advanced sorting technologies: AI and robots will make sorting better

- Improved recovery methods: New ways will make it easier to get metals from products

- Circular economy integration: Products will be made with recycling in mind from the start

New laws are also shaping the recycling industry. Governments are making companies take responsibility for their products’ end-of-life. This leads to better design and more recycling facilities.

Big companies are setting higher goals for using recycled materials. This creates a steady market for recycled metals and encourages more recycling facilities.

In the UK, we expect to see more automation and better quality recycled materials. This will open up new uses for recycled metals, even in tough industries like aerospace and medicine.

Working together on recycling standards and sharing materials across borders will become more common. This will help solve problems like contamination and ensure recycling is done well everywhere.

Conclusion

Metal recycling is key to our modern sustainability efforts. It saves energy, cuts down waste, and protects our planet. It also boosts the economy and helps us care for the environment.

Everyone, from homes to businesses, has a part to play. Just sorting scrap metal or starting recycling programmes can help a lot. Every effort we make brings us closer to a greener future.

By choosing to recycle, we help our communities and industries thrive. This shows the strength of working together. Let’s keep recycling to make our world cleaner and more efficient.

FAQ

What is metal recycling and why is it important?

Metal recycling involves collecting, sorting, and reusing scrap metal. It helps save natural resources and cuts down energy use. It also reduces landfill waste and environmental harm.

Which metals can be recycled?

You can recycle both ferrous and non-ferrous metals. Ferrous metals include steel and cast iron. Non-ferrous metals are aluminium, copper, brass, and precious metals. Knowing the type is key to recycling them right.

How does metal recycling benefit the environment?

Recycling metals saves a lot of energy. Aluminium recycling uses 95% less energy than making new aluminium. Steel recycling saves 75% of energy. It also saves natural resources, cuts down on greenhouse gases, and reduces landfill pollution.

What are the economic advantages of recycling metal?

Recycling metals can make money for businesses. It lowers production costs and creates jobs. It also helps the economy by reducing reliance on imported raw materials.

What challenges does the metal recycling industry face?

The industry faces challenges like contamination and changing environmental laws. It also needs to invest in new technologies to improve efficiency.

How can households participate in metal recycling?

Households can sort and clean recyclable metals. They can use local recycling services. Proper preparation helps in recycling quality and supports community efforts.

What role do businesses play in metal recycling?

Businesses can start recycling programmes and partner with recyclers. They can also invest in sorting systems. These actions reduce waste and bring economic benefits.

How is technology improving metal recycling processes?

New technologies like AI sorting and energy-efficient furnaces are making recycling better. They improve efficiency and reduce environmental impact, leading to a greener industry.

What is the future outlook for metal recycling?

Metal recycling’s future looks bright. Recycling rates are rising, and technology is advancing. Strong policies and public involvement are key to meeting sustainability goals.

Are there regional differences in metal recycling practices?

Yes, recycling varies by region. Some places, like parts of Europe, are leaders in recycling. Others are working to improve their systems and increase metal recovery.